UP TO 100 PIECES PER MINUTE –

VARIABLE SPEED AND MAXIMAL STABILITY

WALTEC‘s spinning machines are available with 6, 12, 18 or even 24 stations. In combination with the linear ESERVO feeder for variable gob weights, S-SERIES can produce up to three different articles simultaneously.

SUSTAINABLE AND INCREASINGLY DIGITALISED CONCEPT –

INNOVATING IN UNISON

WALTEC‘s partnership with SIEMENS features benefits for Polish manufacturer TREND GLASS

LESS DOWNTIME, MORE PRODUCTIVITY –

WALTEC REMOTE SERVICE

With one touch, WALTEC REMOTE SERVICE immediately connects technicians to the WALTEC support experts via smartphones, tablets or smart glasses.

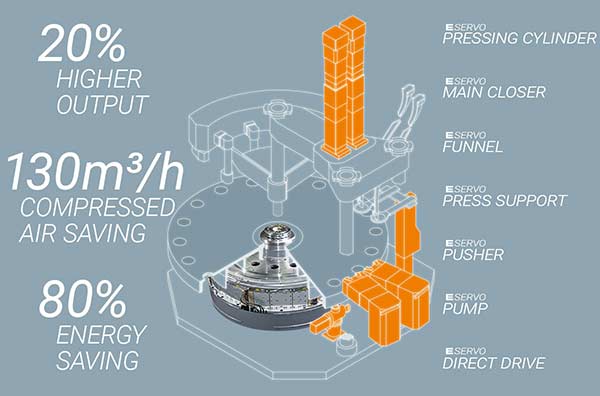

Sustainable Hot End process optimization by

ESERVO PERFORMANCE COMPONENTS

Sustainable Hot End process optimization by

ESERVO PERFORMANCE COMPONENTS

Start saving money now: Boost the output of your press process up to 20%, save energy up to 80%, reduce compressed air up 130 m³/h and improve your sustainability footprint.

ESERVO performance components from WALTEC are compatible with almost all in-market press lines, inclusive those from other press suppliers and can be used to upgrade your existing press line.

SUSTAINABILITY AND MAXIMIZED PROCESS EFFICIENCY:

RE-ENGINEERING THE PRESS-BLOW PROCESS

A second to none sustainable solution for the press-blow process: WALTEC`s Industry 4.0 compliant W–SERIES offers innovative technology, including energy savings and unprecedented process accuracy and repeatability, leading to a new level of process efficiency.

COME TOGETHER: FAIRS

Let us get together and meet WALTEC at one of the following international fairs and exhibitions:

English

English Dansk

Dansk Español

Español پارسی

پارسی Français

Français हिन्दी; हिंदी

हिन्दी; हिंदी Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Română

Română Русский

Русский Slovenščina

Slovenščina Svenska

Svenska 中文(简体)

中文(简体)